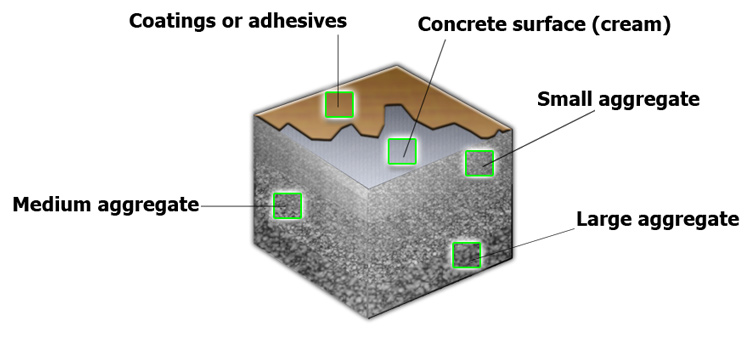

Cross Section of Your Concrete Floor

To fully understand the techniques of the concrete polishing process, it is also important to understand the floor that you are working on. Here is a cross section of common concrete slab floor and the versions of aggregate involved within it, as defined by the Concrete Polishing Association of America.

- Coatings and adhesives:

- Before working on the concrete surface itself, you may have to remove coatings (like epoxies) or adhesives (like carpet adhesives or black mastics).

- Little aggregate exposure:

- The cream look requires little surface cut depth and has little aggregate exposure.

- Small aggregate:

- The salt and pepper look requires a 1/16-inch surface cut depth and has fine aggregate exposure with little or no medium aggregate exposure in random locations.

- Medium aggregate:

- The medium aggregate profile requires a 1/8-inch surface cut depth and has a medium aggregate exposure with little or no large aggregate exposure at random locations.

- Large aggregate:

- The large aggregate requires a 1/4-inch surface cut depth and has a large aggregate exposure with little or no fine aggregate exposure at random locations

Step-by-step options in the mechanical polishing process

| Cream Surfaces 100G Rescue 200G KR Pro 400G KR Pro 1800 KR Pro 3000 KR Pro (NOTE: Using densifiers and burnishing will be determined by the contractors involved in the project with the recommendation of the densifier manufacturer. The contactor has the option to color the floor as well as using post-polish sealer. These steps will be determined at the contractor's disccretion.) |

Salt and Pepper Surfaces 70G BevelKut™ 120G BevelKut™ 100G Rescue™ 200G KR Pro 400G KR Pro 800G KR Pro 1800G KR Pro 3000G KR Pro (NOTE: Using densifiers and burnishing will be determined by the contractors involved in the project with the recommendation of the densifier manufacturer. The contractor has an option to color the floor as well as using post-polish sealer. These steps will be determined at the contractor’s discretion.) |

Large Aggregate Surfaces 25 Twin Segment 70G BevelKut™ 120G BevelKut™ 100G Rescue 200G KR Pro 400G KR Pro 800G KR Pro 1800 KR Pro 3000 KR Pro (NOTE: The heavy aggregate concrete polishing process would be the same as the one used above, other than using KR10 with full-face cutters and/or spending additional time in the 25-grit process. Using densifiers and burnishing will be determined by the contractors involved in the project with the recommendation of the densifier manufacturer. The contractor has an option to color the floor as well as using post-polish sealer. These steps will be determined at the contractor’s discretion.) |