Self-cleaning KleanRite™ Reverse Flow Vacuum Systems are a contractor’s best friend, cutting costs and time on the job

Any contractor knows that cleanup is an extremely important component on any cement scarifying, grinding and/or polishing job site. Kut-Rite Manufacturing has designed and built a complete line of vacuums with the interests of the operator first and foremost in mind.

The KleanRite™ Reverse Flow (RF) vacuum systems are capable of maintaining constant suction (cubic airflow per minute, commonly known as CFM) and impressive water lift (inches of water/debris moved), creating the best combination of consistent power, filtration and work consistency.

Thanks to innovative engineering, this line of vacuums is the contractor’s best friend. CFM and water lift work together in any vacuum. CFM measures air pulled through a two-inch opening in a minute’s time. While airflow is a crucial factor in evaluating vacuum power, it must be factored in with water lift to measure true effectiveness. Water lift is a calculation of how many inches up a tube the vacuum motor’s intake can pull up water. Suction gauges on vacuums cleaners, for instance, are calibrated in “inches of water lift.” This all contrasts with CFM, which measures how much air flows into the same intake. Water lift is important to keep the air moving, especially over long distances or when the tool being used to vacuum has a small air opening.

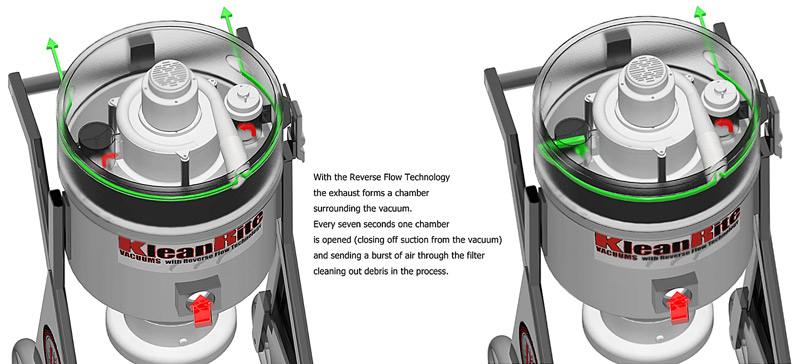

In the reverse flow system, the cartridge filters are sequentially pulsed with a burst of air from the blower exhaust chamber every 7 seconds. This self-cleaning process ejects all dust and debris from the surface of the filter, allowing for a continuous flow of air and no loss of suction. Many vacuums lose their ability to keep up with the particulates while collecting fine dust. This “fine dust” includes matter such as concrete, wood, terrazzo, marble, drywall, powder coating, fiberglass and much more. The KleanRite™ dust collection system is also ideal for decorative concrete cleanup; drum sanders for wood sanding; and most other types of floor preparation.

The reverse flow technology allows the operator to ensure continuous suction, keeping production time up – and downtime to a minimum.

Additional features of the Kut-Rite reverse flow line include Ultra-Web Filters’ technology. Ultra-Web Filters outperform and outlast other filters on the market today and offer higher performance, increased efficiency, long filter life and greater value. Over the past three decades, engineers have developed, produced and improved Ultra- Web nanofiber filter media – a high performance alternative to commodity-type filter media that captures submicron dust particles on the surface of the media. In comparison, cellulose, blended, spunbond and meltblown media are depth-loading media that allow particulates to penetrate deep into the filter and choke off airflow. By keeping more particles on the surface of the filter, Ultra-Web Filters allows the reverse- flow action to perform at top capacity.

Other features of the reverse flow system are one-of-a-kind debris removal valve that makes the vacuums easier and safer to use; an ergonomic dolly system with locking casters; aluminum construction that eliminates corrosion and reduces weight; innovative electrical protection; spacious design for effortless maintenance; and one-year warranty.